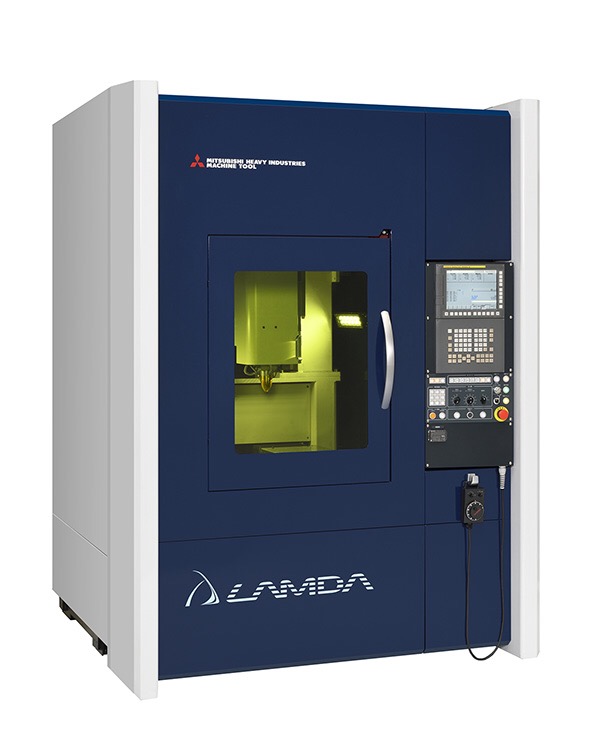

MHI demonstrates metal 3D additive manufacturing technology-US Trade Fair “RAPID + TCT 2019”

Mitsubishi Heavy Industries Machine Tool Co., Ltd .:

We will start offering “Metal 3D Printer”, which uses our own deposition method (Note 1), to overseas markets.

The aim is to raise awareness and gain a foothold in the United States, which is driving the world’s fastest growing 3D printer market.

Trade fair “RAPID + TCT 2019” of advanced solid modeling technology to be held in Detroit, Michigan from May 20 to 23

Proposal for “Metal 3D Printer”:

New technology required for commercialization of metal 3D printers

Monitoring feedback function

Local shield function

Show off.

These two functions are the world’s first practical technologies.

Mitsubishi Heavy Industries Machine Tool Co., Ltd. uses “the results that TRAFAM has developed from NEDO on a contract basis (Note 2)”.

1

It is called Directed Energy Deposition (DED), and it is an additive manufacturing process that melts materials using heat energy concentration.

2

This product utilizes the results of the support project of the New Energy and Industrial Technology Development Organization (NEDO).

Proprietary deposition method:

A technology that sprays powder continuously from a nozzle and irradiates a laser to melt and solidify it.

The molding speed is 10 times faster than the powder-bed method.

Since a tank of metal powder is not used, large-sized formation is possible.

possible to switch the material on the way to supply the material continuously.

possible to form multi-layered material parts made of multiple different materials.

In the future, it is also expected to be applied to the development of functionally graded materials in which materials of different compositions are joined.

Monitoring feedback function:

Stability of modeling quality is improved, and modeling of large parts is possible.

The monitoring function is a system that monitors the build condition using a camera or sensor.

Automatic optimization of molding conditions, no need for trial and error.

Feedback function:

Control modeling conditions such as laser output in real time based on monitoring results.

It stabilizes the melting and solidification of metals.

Local shield function:

We are aiming to commercialize the local shield function.

The shielding function is the function of eliminating oxygen in the surrounding environment during modeling and preventing oxidation of the molten metal.

It enables modeling of materials that resist oxidation such as titanium and aluminum in the air environment without using a chamber.

With this feature, there is no restriction on the size of the object.

It can be applied to the modeling of large parts, which is an issue in the aerospace industry etc

Mitsubishi Heavy Industries