Using seawater: convert cryogenic liquid hydrogen to gas!

– Quadrupling the processing capacity of liquid hydrogen vaporizers –

-Jointly developed by Iwatani and Sumitomo Precision Industries-

We will deliver a report from the latest Nikkei article.

Iwatani and Sumitomo Precision Industries:

Started joint development of a “vaporizer” that converts liquid hydrogen into gas.

It is characterized by “using seawater to turn cryogenic liquid hydrogen into gas.”

“Vaporizer”, a device that turns liquid hydrogen into gas:

By “flowing seawater outside the tube containing liquid hydrogen,

” temperature is efficiently transmitted.

Achieves up to four times the processing capacity of the previous model.

Combining the technologies of both companies,

we will contribute to the supply network for the realization of a hydrogen society.

https://www.nikkei.com/article/DGXZQOUF16A9K0W3A610C2000000/

Iwatani Industry

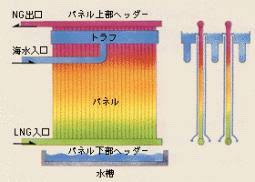

Concluded a joint development contract for an open rack vaporizer* for liquefied hydrogen.

We will construct a large-capacity hydrogen supply system

assuming large-scale demand such as power generation.

Development of a large liquefied hydrogen vaporizer, which is the main equipment.

We will utilize the technology and knowledge related to liquefied hydrogen that Iwatani has cultivated.

Sumitomo Precision Industries:

We will make use of our half-century of experience in manufacturing large-capacity LNG vaporizers.

Researching the development of a state-of-the-art liquefied hydrogen vaporizer.

We will combine the know-how of “Sumitomo Precision Industries’ development capabilities

and low-temperature liquefied gas vaporization technology.”

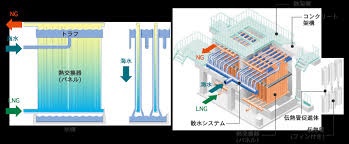

What is an open rack vaporizer for liquefied hydrogen:

Seawater is flowed on the outer surface of the panel

on which the heat transfer tubes are arranged.

This is a method to vaporize the liquefied hydrogen inside.

This method is used all over the world as an LNG vaporizer.

Using seawater as an external heat source:

The operation cost is economical,

and the structure facilitates operation monitoring and maintenance inspection.

With this kind of vaporizer, Sumitomo Precision Products has outstanding reliability and safety.