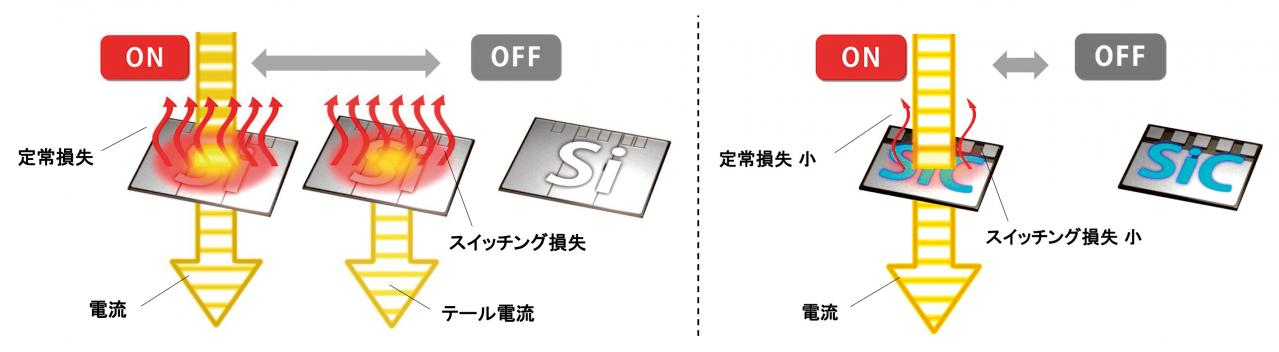

The left is a conceptual diagram of Si power semiconductors and the right is a conceptual diagram of transistors in SiC power semiconductors during switching operation. When an electric current is passed through a Si power semiconductor, part of the electric power is lost by heat. In addition, the switching loss is large due to the tail current when the switch is turned on and off. 20% of HEV power loss is due to power semiconductors. SiC power semiconductors have a small steady-state loss due to heat and a small tail current, so a switching loss is also small.

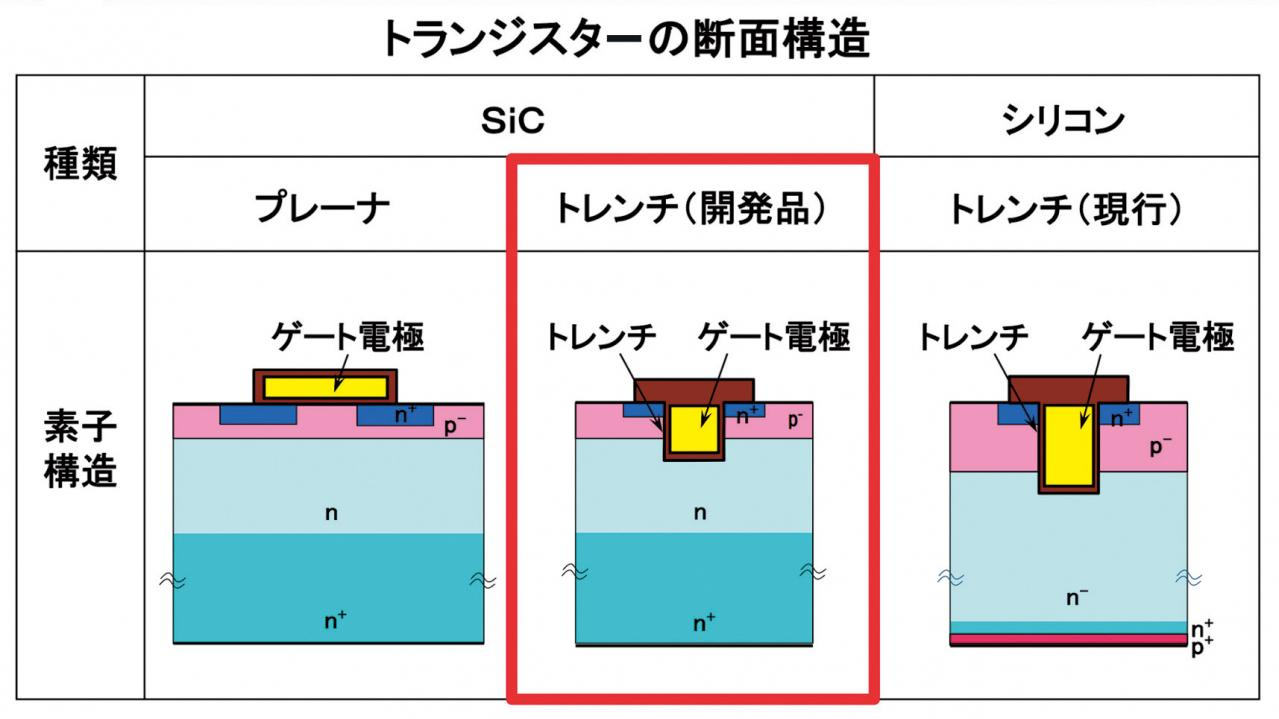

The developed SiC transistor has a cell width of 4-5 microns. A trench structure is used to dig fine grooves in the semiconductor. Dry etching, which is commonly used in Si semiconductors, is a processing method that uses gas and plasma. The gate electrode is an electrode that controls the ON / OFF of the current.

Toyota: Superiority of power semiconductor SiC: Adopted by Toyota MIRAI

Toyota,

Denso,

Toyota Central R & D Labs,

Promote joint development by the three companies.

SiC power semiconductors have the potential to improve HEV fuel economy by 10%.

Development of SiC power semiconductors:

Toyota is a top runner in the development of SiC power semiconductors.

It was adopted in Toyota’s new MIRAI with the aim of putting it into practical use in 2020.

SiC = Silicon Carbide:

It is a compound of silicon and carbon and has the hardness next to diamond.

High-purity single crystal SiC:

Toyota, Denso, and Toyota Central R & D Labs have developed a high-purity, single-crystal type that is extremely difficult to produce.

Power Semiconductor SiC:

Power semiconductors are widely used in HEVs.

25% of it is used in PCU (power control unit).

HEV PCU:

The PCU, which is the heart of the HEV, is an important device that controls the current between the battery and the motor.

Improved fuel economy of HEVs:

In HEVs that claim low fuel consumption, 20% of power loss is due to power semiconductors.

That is, improving the efficiency of power semiconductors is directly effective in improving fuel efficiency.

In-house development of power semiconductors:

Toyota has been developing power semiconductors in-house since the first Prius.

With Denso of Toyota Group

Toyota Central R & D Labs

Started basic research in the 1980s

In 2007, Toyota has been developing technology for practical use.

Efficiency of SiC power semiconductors:

SiC power semiconductors are more popular than the current mainstream Si (silicon) power semiconductors.

It is highly efficient, compact, and can be driven at higher frequencies.

5% improvement in fuel efficiency with prototype vehicle:

Toyota has installed a PCU that uses SiC power semiconductors on the Prius.

It was confirmed that the prototype vehicle improved fuel efficiency by more than 5%.

10% improvement in fuel efficiency with HEV:

An improvement of 5% can be seen without fine adjustment.

Power semiconductors are extremely important for HEVs.

In the future, it aims to improve fuel efficiency by 10%.

It can be said that it is a key technology in the electrification of automobiles along with batteries.

Motor-FanTECH