Taisei Corporation: Fixing a large amount of CO2 with concrete:

-“T-e Concrete / Carbon-Recycle”-

Taisei Corporation:

“T-e Concrete / Carbon-Recycle”, which fixes a large amount of CO2, was applied to the pavement.

A stone-like building material pavement block “T-razzo” made of environment-friendly concrete is also used.

Pavement block “T-razzo”:

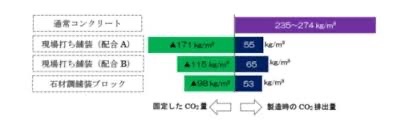

As a result of paving 5.3m3 cubic meters with “T-razzo”,

Compared to conventional concrete pavement, we were able to reduce CO2 emissions by a total of 1.5 tons.

What is T-eConcrete / Carbon-Recycle:

A type of “T-e Concrete” series that started to be applied in 2014.

The raw material is CO2 recovered from factory exhaust gas.

Calcium carbonate powder and blast furnace slag, which is an industrial by-product, are used as materials.

Significant CO2 reduction with T-eConcrete:

No special equipment is required to manufacture the T-e Concrete.

Even in construction that uses only a small amount of concrete, CO2 can be significantly reduced.

Can fix 70-170 kg of CO2 per 1 m3,

The CO2 emission balance in concrete manufacturing

It becomes carbon negative.

Taisei Corporation:

We would like to spread concrete pavement using calcium carbonate and contribute to carbon negative.

Nikkei Cross Tech (xTECH)