Mitsubishi Heavy Industries: Demonstrating CO2 capture technology KS-21: Mongstad in Norway

-Commercialization of amine absorber-

Mitsubishi Heavy Industries Engineering:

On March 4, Norway announced that it would start a demonstration test of carbon dioxide (CO2) capture technology in May.

Demonstration of CO2 capture technology:

In the demonstration, we used the amine absorber “KS-21” that absorbs CO2, which was jointly developed with Kansai Electric Power Co., Inc.

It is expected that the operating cost of CO2 recovery equipment will be reduced. Demonstration will be conducted until around summer.

Commercialization of “KS-21”:

Mitsubishi Heavy Industries Engineering aims to commercialize “KS-21” by the end of this year.

“KS-21” is an absorbent that has undergone technological improvements through joint research with Kanden.

Compared to the conventional product “KS-1”, it has lower volatility and is less likely to deteriorate.

There is a merit that the frequency of replacement of the absorbent liquid can be suppressed during operation.

Denki Shimbun website

https://www.denkishimbun.com/archives/111543

Mitsubishi Heavy Industries | CO2 Recovery Plant

We have jointly developed and commercialized CO2 capture technology (KM CDR Process ™) with Kansai Electric Power Co., Inc.

The proprietary amine absorber KS-1 ™ is used.

Plants using this process are in operation at 13 locations around the world (as of February 2019).

Compatible with a wide variety of exhaust gas sources,

Energy saving process plant,

Absorbent liquid with less renewable energy and deterioration.

CO2 absorption process:

After the exhaust gas containing CO2 is cooled in the exhaust gas cooling tower, it comes into contact with the alkaline KS-1 ™ absorption liquid in the absorption tower, and the CO2 in the exhaust gas is absorbed.

The absorption liquid containing a large amount of CO2 is sent to the regeneration tower and heated by steam to release CO2 and be regenerated.

The regenerated absorption liquid is returned to the absorption tower and reused.

Performance of this process:

90% or more of CO2 contained in the target gas is recovered (purity of 99.9vol% or more).

In addition, the unique energy-saving regeneration system reduces steam consumption.

https://www.mhi.com/jp/products/engineering/co2plants.html

Mitsubishi Heavy Industries, Ltd. Global Website |

Mitsubishi Heavy Industries Engineering to test carbon capture technology at Technology Centre Mongstad in Norway

2021-03-04

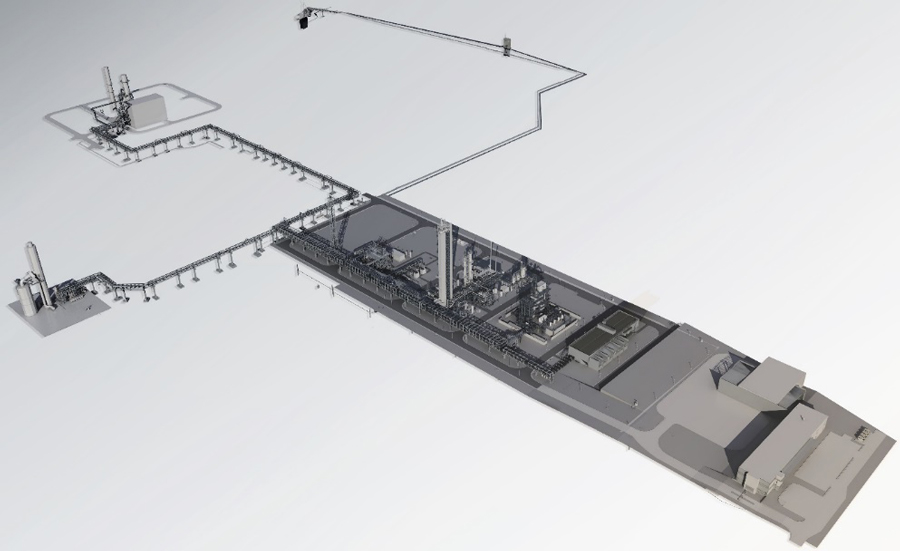

Mitsubishi Heavy Industries Engineering Technology Centre Mongstad

・ Testing of proprietary solvent KS-21TM will start from May 2021 at TCM

・ TCM offers state-of-the-art facilities and expertise to ensure successful demonstration

・ MHIENG aims to expand its carbon capture business in the United Kingdom and Europe

Mitsubishi Heavy Industries Engineering (MHIENG), part of Mitsubishi Heavy Industries (MHI) Group,

has entered into an agreement with Technology Centre Mongstad (TCM) to test its proprietary solvent for capturing CO2 at the amine plant located in Mongstad, Norway.

The test campaign will start in May.