Mayekawa Mfg. Co., Ltd .: “Bone-removing robot” for pork thigh: Same speed as humans

-Achieving the same speed as humans with AI installed-

Mayekawa Mfg. Co., Ltd .:

Extract the hip bones and coccyx from the pork thigh.

We have developed a bone removal robot CELLDAS.

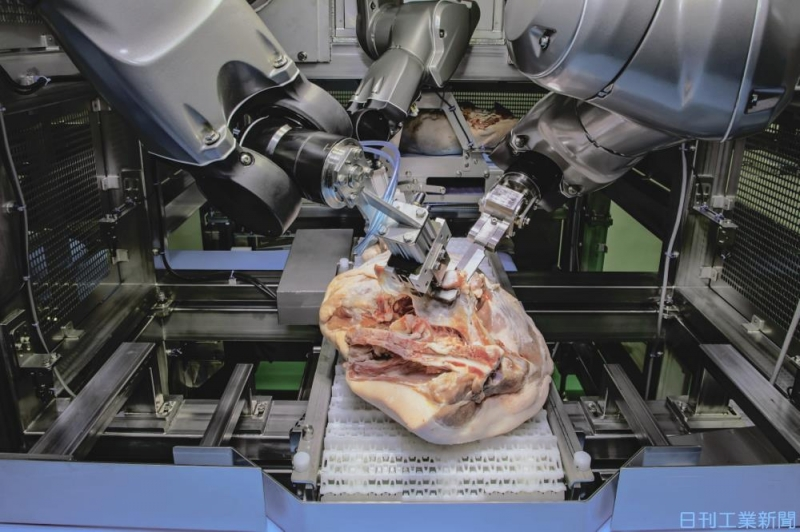

Bone removal robot CELLDAS:

In combination with a device that extracts the femur, etc., the deboning work of pork thigh can be fully automated.

The price is 240 million yen for “CELLDAS 6 bone removal line”.

Aim to sell one line in the first year.

Bone removal line flow:

Remove bone from one block of meat with three 6-axis arms.

The recognition unit 3D sensor captures the three-dimensional shape and the bone arrangement with X-rays.

There are individual differences in the shape and orientation of the bones, and AI has improved the identification accuracy.

After identifying the coordinates of the bone, send it to the bone removal work robot unit.

Measure the three-dimensional shape again and calculate the trajectory to insert the knife.

Same speed as humans:

Hold the meat with the arm, just like human work.

Insert the knife with another arm.

The processing speed is 90 per unit per hour. Bone is removed in 40 seconds.

Achieved the same speed as the worker.

Completed deboning work with a robot:

It can be used for a wide range of bone removal by developing programs for other bones such as the femur.

We plan to develop forefoot deboning and treatment of bone-in meat.

Develop a mixed pork processing line based on Cerdas.

Meat Center:

Labor shortage has become an issue.

In addition to automation

Thigh meat in the morning

Shoulder meat in the afternoon, etc.

You can change the processed items with one program.

It will be easier to handle variable production.

New switch

Hamdas-RX: Automatic bone removal robot for pig thighs

Hamdas-RX:

The world’s first robot with a knife.

For the first time in the world, we have realized the automation of scoring, which was said to be impossible.

This device can handle 60% of the thigh bone removal work.

By measuring the bone position one by one

Cut at the position corresponding to individual differences,

We provide high yields.

Product Information | Mayekawa Mfg. Co., Ltd.