Mitsubishi Electric: 60% improvement in SiC and GaN slice: Wafer slicing for next-gen semiconductors

Mitsubishi Electric: Multi-wire EDM machine

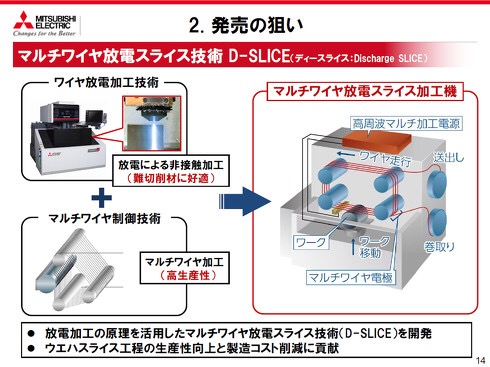

Mitsubishi Electric has been developing a new multi-discharge slice technology “D-SLICE”.

On November 1, 2019, we announced the release of the DS1000 multi-wire electric discharge slicing machine.

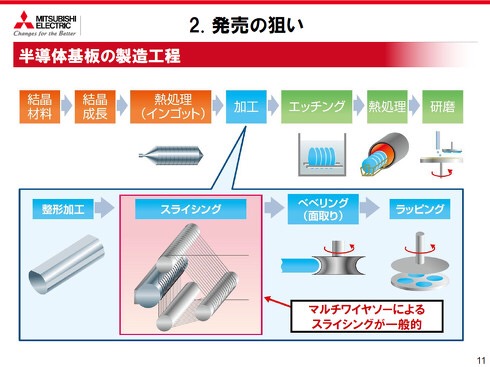

Next-generation semiconductor materials: Wafer slices

We propose the use of next-generation semiconductor materials such as SiC (silicon carbide) and GaN (gallium nitride) in the wafer slicing process.

“D-SLICE”: New multi-discharge slice technology

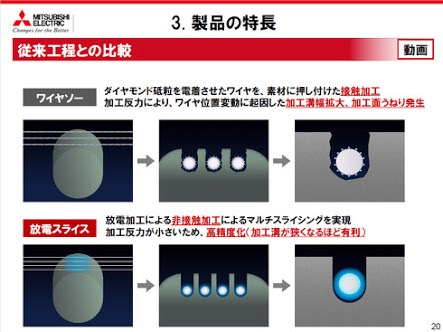

Combines wire EDM technology and multi-wire control technology.

Slicing like a multi-wire saw is possible by electrical discharge machining.

Slicing by multi-wire electric discharge machining and cutting out wafers

Easily process for ’difficult-to-cut materials’ such as SiC and GaN.

It is possible to minimize the groove width by non-contact machining, which is a feature of EDM.

Running costs can also be reduced because no abrasive grains are required.

MONOist

https://monoist.atmarkit.co.jp/mn/spv/1909/13/news044.html

http://www.mitsubishielectric.co.jp/news/2019/0912.html?cid=rss