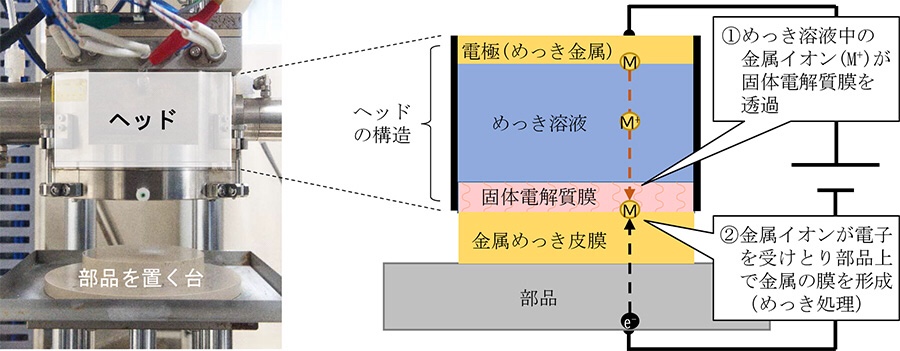

Stamp type plating equipment

Two installed on the left and right. As for the size, one unit is about 1 m in width × about 1 m in depth × about 2 m in height

Conventional plating process

Multiple aquariums and equipment for plating solutions and waste liquid treatment

Features of “Stamp type plating device” (structure of the tip head)

Toyota Launches Stamping-Type Plating Machine that Significantly Reduces Environmental Impact and Transforms Plating Process

Toyota City, Japan, June 30, 2020―

Toyota) today

announced that it has developed a world’s first*1 stamping-type plating technology

that uses a polymer membrane (solid electrolyte membrane), through which metal ions can pass, to apply plating, like a stamp, only to areas requiring plating.

The technology

is used in the plating process for forming copper, nickel, and other metal coatings on substrates in the process of manufacturing electronic parts.

Toyota has also announced a collaboration with Mikado Technos Co., Ltd. and Kanematsu Corporation to manufacture and sell,

and therefore expand the use of, new plating machines based on this new technology.

The machines will be launched on July 1.

This new stamping-type plating machine

eliminates the need of a dipping process where parts to be plated are completely immersed in multiple baths of plating solution, which is required in the most common plating process at present.

As a result, waste solution

can be dramatically reduced to about one-thirtieth and CO2 emissions to about one-third, which contributes to a significant reduction in environmental impact.

The technology also reduces plating time and process footprint.

Corporate | Global Newsroom | Toyota Motor