冲压式电镀设备

左右两个安装。至于尺寸,一个单元的宽度约为1 m×深度约为1 m×高度约为2 m

常规电镀工艺

用于电镀液和废液处理的多个水族箱和设备

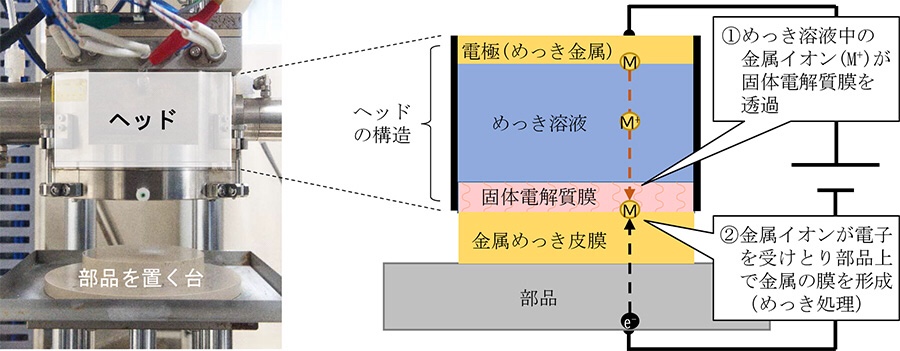

“邮票型电镀装置”的特征(尖端头的结构)

丰田:销售邮票型电镀设备:大大减少对环境的影响

丰田:

“邮票式电镀设备”

丰田公司开发了世界上第一台* 1技术的“冲压式电镀设备”。

执行电镀,以便仅将压模应用于需要电镀的区域。

电子元件制造工艺:

允许金属离子通过的聚合物膜(固体电解质膜)用于在基板上形成诸如铜或镍之类的金属膜。

Mikado Technos和Kanematsu:

在Mikado Technos和Kanematsu的合作下,我们决定利用这种新技术制造和销售新的电镀设备。

它将于7月1日开始销售。

“工厂二氧化碳零挑战”:

将来,我们将继续在集团中引入这种“冲压式电镀设备”,并在制造阶段稳步减少二氧化碳的排放。

全球新闻室|丰田官方网站

https://global.toyota/jp/newsroom/corporate/33011805.html

Toyota Launches Stamping-Type Plating Machine that Significantly Reduces Environmental Impact and Transforms Plating Process

Toyota City, Japan, June 30, 2020―

Toyota) today

announced that it has developed a world’s first*1 stamping-type plating technology

that uses a polymer membrane (solid electrolyte membrane), through which metal ions can pass, to apply plating, like a stamp, only to areas requiring plating.

The technology

is used in the plating process for forming copper, nickel, and other metal coatings on substrates in the process of manufacturing electronic parts.

Toyota has also announced a collaboration with Mikado Technos Co., Ltd. and Kanematsu Corporation to manufacture and sell,

and therefore expand the use of, new plating machines based on this new technology.

The machines will be launched on July 1.

This new stamping-type plating machine

eliminates the need of a dipping process where parts to be plated are completely immersed in multiple baths of plating solution, which is required in the most common plating process at present.

As a result, waste solution

can be dramatically reduced to about one-thirtieth and CO2 emissions to about one-third, which contributes to a significant reduction in environmental impact.

The technology also reduces plating time and process footprint.

Corporate | Global Newsroom | Toyota Motor