三菱化学:量产大口径GaN单晶衬底:2、4、6英寸衬底

-实现了下一代EV技术和非接触式充电-

三菱化学:

三菱化学对大直径GaN单晶衬底的量产寄予厚望。

EV非接触充电技术的实现:

可在驾驶时对电动汽车 (EV) 进行非接触式充电的下一代 EV 技术即将实现。

GaN单晶衬底:

GaN单晶衬底为

可以在更高的电流下工作,

实现高耐压功率半导体,

电子设备可以做得更高效、更小。

新材料为电动汽车开辟了新的可能性。

三菱化学:

藤户武:

EV 非接触式充电系统在行驶中,

用于驱动轮毂电机

需要 GaN 上的 GaN。

已安装板生产设备:

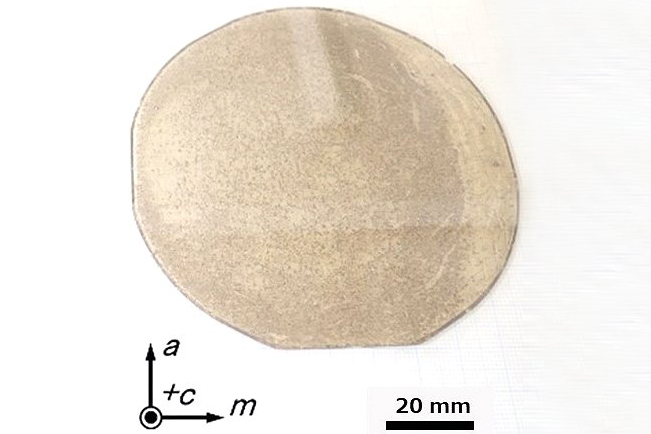

三菱化学与日本钢铁厂合作,在北海道室兰市,

安装了能够生产 2、4 和 6 英寸基板的批量生产设施。

市场供应将于 2022 年初开始。

采用液相生长法:

本设备采用“液相生长法”。

与传统的气相生长相比,缺陷密度可以抑制到 1/100 到 1/1000。

实现液相生长方法需要制造条件的重大突破。

开发液相生长方法大约需要10年时间。

单晶再沉淀:

液相生长法是在高温高压下进行的。

对于超临界状态的液氨,

熔化 GaN 多晶,

从那里,单晶被重新沉积。

传统的:

为了熔化GaN,它被提高到2000个大气压,但大型设备无法承受这种压力。

这次:

三菱化学为氨设计了一种添加剂矿化剂,以便在 1000 个大气压下可以溶解大量的 GaN(藤户先生)。

与日本钢厂的合作:

“开发可承受1000个大气压的大型装置”是极其困难的。

这是通过“与拥有石英晶体合成技术和大型设备技术的日本钢厂合作”实现的。

使用领域:

预计通过液相方法增加直径有助于设备的发展。

下一代电动汽车技术和

电机小型化,

高输出高亮度光源,

信息通信领域,

新开关

Completion of the world’s largest manufacturing facility for gallium nitride (GaN) substrates

The Japan Steel Works, LTD.

Mitsubishi Chemical Corporation

have completed construction of a demonstration facility for mass production of gallium nitride (GaN) single-crystal substrates in the premises of the Muroran Plant of Japan Steel Works in collaboration.

We will conduct verification tests for mass production of 4-inch GaN single-crystal substrates throughout FY2021, and start market supply FY2022. 1.

Background GaN is a material used to create ultra-high-efficiency devices,

employing its enhanced efficiency and durability.

In addition, it is expected to have an environmental benefit

since the material can reduce CO2 emissions with a drastic reduction of power consumption.

Promising applications of GaN not only include blue LEDs

but the fields listed below as well:

1 High-power and high-intensity light source GaN is expected to be applied to high-intensity and high-power lasers, high-efficiency illumination, and new-generation displays.

2 Telecommunications GaN will contribute to 5th Generation Mobile Communication System (5G) such as high- frequency devices and optical communication devices that can

instantaneously transmit and

receive large amounts of data, and

even to post-5G. GaN,

with a higher processor frequency than currently prevailing silicone substrates, can also contribute to power saving of servers and base stations.

3 Power semiconductor In recent years, demands for power semiconductors that allow the downsizing of devices and instruments in particular have been increasing.

While silicone substrates currently predominate, demands for high-voltage power semiconductors that can attain higher-current operations are rising more than ever.

https://www.m-chemical.co.jp/en/news/2021/__icsFiles/afieldfile/2021/06/09/GaNeng.pdf