COVID-19: Mask made in Japan, Iris Ohyama: Relieve “stuffiness”, nanofiber processing

COVID-19:

Iris Oyama:

Finally, the Japanese mask production line will start operation at the Kakuda Factory in Miyagi Prefecture.

Domestic production of new product “Nano Air Mask” started.

7 pieces: Price is 498 yen

Size: Normal (PK-NI7L) and small (PK-NI7S)

Usually, it will be released in mid June, and the smaller one will be released in September.

Originally developed in Japan:

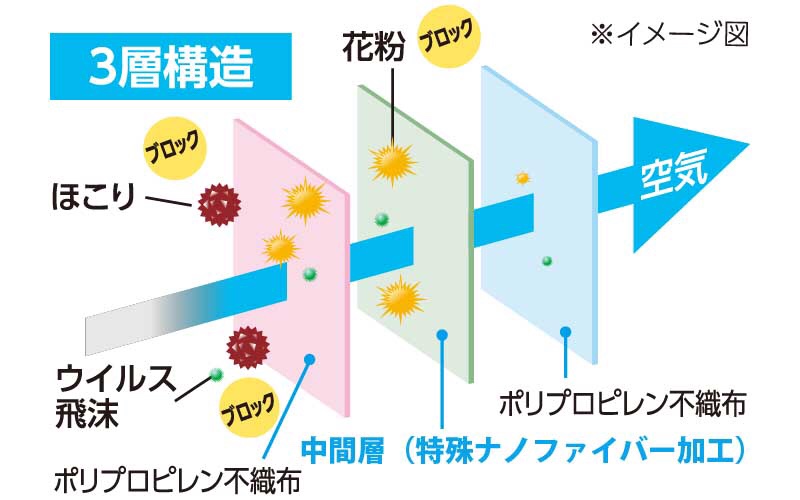

The middle layer that has undergone special nanofiber processing is used.

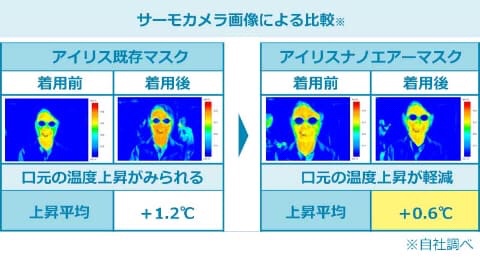

When wearing a mask, “The temperature rise around the mouth is reduced to about half compared to the conventional product.”

With this, “we can alleviate stuffiness and stuffiness when we wear”

Running and mountaineering,

In a crowded train,

In summer and rainy season,

It can be used comfortably even when you feel uncomfortable wearing a mask.

Impress Watch

https://www.watch.impress.co.jp/docs/news/1256931.html

Iris Oyama: Strengthening domestic mask production to 150 million pieces/month

Considering the impact of China’s soaring prices on important mask materials/nonwovens.

Kakuda Factory:

Non-woven fabrics for masks (meltblown, spunbond)/material manufacturing equipment will be newly installed in the Kakuda Factory.

We will increase the in-house production rate in Japan and review the supply system that depends on China.

This time the production equipment is being enhanced:

With this expansion, we have realized a system that can supply 230 million sheets/month in Japan, including two factories in China.

The Kakuda Factory will also create 100 new jobs.

Mask supply system in Japan:

Japan (Kakuda Factory): 150 million sheets/month

China (Dalian Factory, Suzhou Factory): 80 million sheets/month

Impress Watch