Asahi Kasei: Making LIB solvent from CO2:

-Contributing to reducing CO2 emissions-

Asahi Kasei:

We have developed “a technology to make a solvent for lithium-ion batteries from CO2”.

Nihon Keizai Shimbun

(June 17th)

“Asahi Kasei will put it to practical use in 2023,” It reported.

Solvent for LiB electrolyte:

We have developed “a technique for producing a solvent used for an electrolytic solution, which is a main component of a battery”.

Solvent preparation using CO2 as a raw material:

In the conventional technique, a solvent is prepared from a fossil raw material.

With this technology, a solvent is prepared from CO2.

Licensed for technology:

Due to the simplicity of the process, the technology is licensed without enclosing it.

The initial cost of the equipment is 30% cheaper than the existing method.

Traders Web

https://finance.yahoo.co.jp/news/detail/20220617-10000028-dzh-stocks

Asahi Kasei : Fabriquer du solvant LIB à partir de CO2 :

-Contribuer à la réduction des émissions de CO2-

Asahi Kasei :

Nous avons développé « une technologie pour fabriquer un solvant pour batteries lithium-ion à partir de CO2 ».

Nihon Keizai Shimbun

(17 juin)

“Asahi Kasei le mettra en pratique en 2023”, a-t-il rapporté.

Solvant pour électrolyte LiB :

Nous avons développé “une technique de production d’un solvant utilisé pour une solution électrolytique, qui est un composant principal d’une batterie”.

Préparation de solvant utilisant le CO2 comme matière première :

Dans la technique conventionnelle, un solvant est préparé à partir d’une matière première fossile.

Avec cette technologie, un solvant est préparé à partir de CO2.

Licencié pour la technologie :

En raison de la simplicité du processus, la technologie est concédée sous licence sans l’enfermer.

Le coût initial de l’équipement est 30% moins cher que la méthode existante.

Web des commerçants

Asahi Kasei: Herstellung von LIB-Lösungsmittel aus CO2:

-Beitrag zur Reduzierung der CO2-Emissionen-

Asahi Kasei:

Wir haben „eine Technologie entwickelt, um aus CO2 ein Lösungsmittel für Lithium-Ionen-Batterien herzustellen“.

Nihon Keizai Shimbun

(17. Juni)

„Asahi Kasei wird es 2023 in die Praxis umsetzen“, berichtete er.

Lösungsmittel für LiB-Elektrolyt:

Wir haben “eine Technik zur Herstellung eines Lösungsmittels entwickelt, das für eine Elektrolytlösung verwendet wird, die ein Hauptbestandteil einer Batterie ist”.

Lösungsmittelherstellung mit CO2 als Rohstoff:

Bei der herkömmlichen Technik wird ein Lösungsmittel aus einem fossilen Rohmaterial hergestellt.

Bei dieser Technologie wird aus CO2 ein Lösungsmittel hergestellt.

Lizenziert für Technologie:

Aufgrund der Einfachheit des Verfahrens wird die Technologie lizenziert, ohne sie beizufügen.

Die Anschaffungskosten der Ausrüstung sind 30 % günstiger als bei der bestehenden Methode.

Trader Web

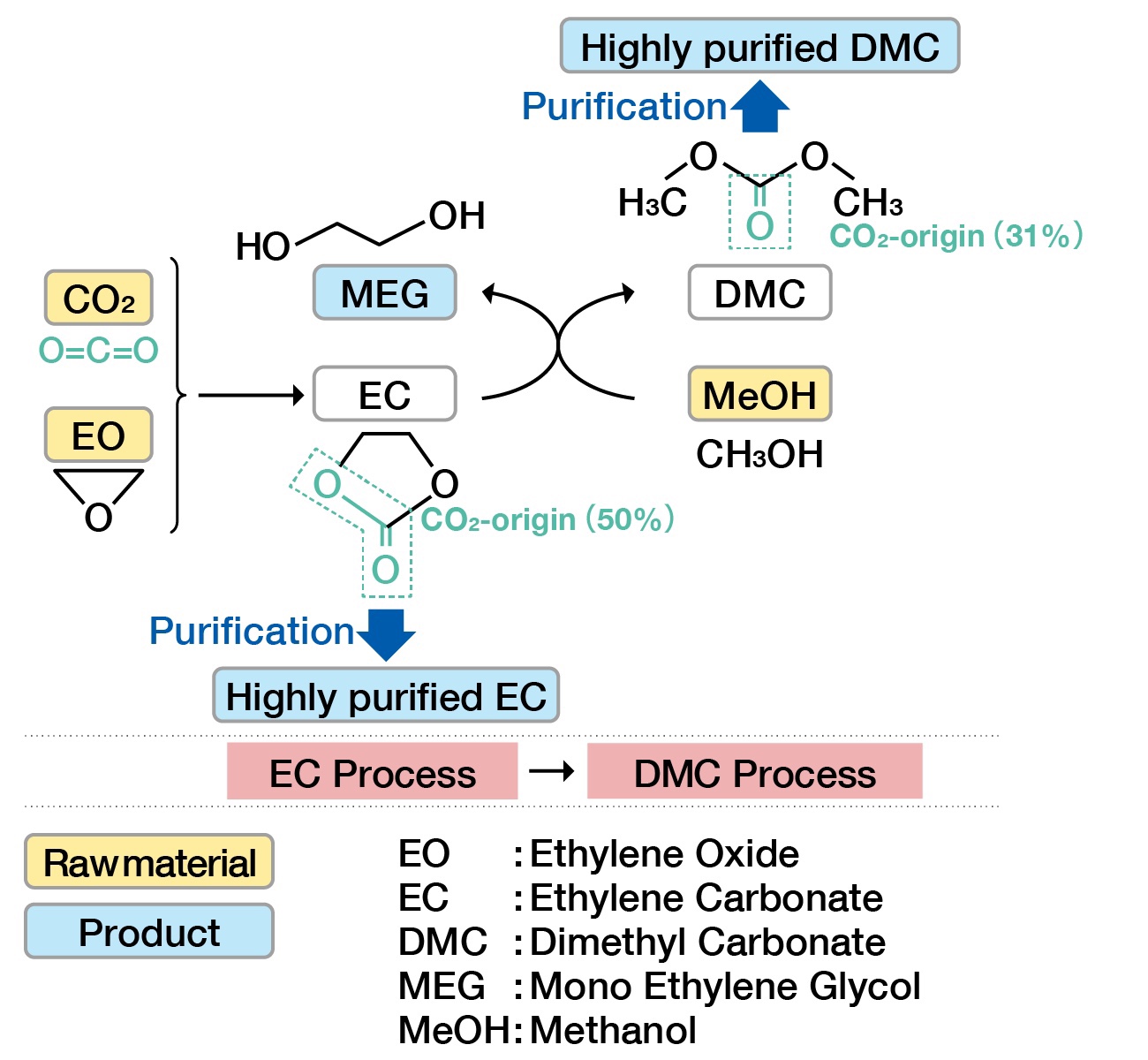

Technology Licensing Business

– Asahi Kasei Highly purified carbonate

(ethylene carbonate and dimethyl carbonate) production technology Carbonate

is a commodity organic chemical used as solvents, paints, pharmaceutical raw materials, gasoline additives, electrolyte components for lithium-ion battery(LIB), etc.

Ethylene carbonate (EC) is white solid, and dimethyl carbonate (DMC) is colorless liquid at normal temperature.

We have started licensing

the production technology of highly purified EC and highly purified DMC by utilizing the PC production technology (2019).

50 wt% of EC and 31 wt% of DMC are originated from CO₂ respectively,

so they are environmentally friendly processes that consume CO₂.

Major application of highly purified carbonate solvent

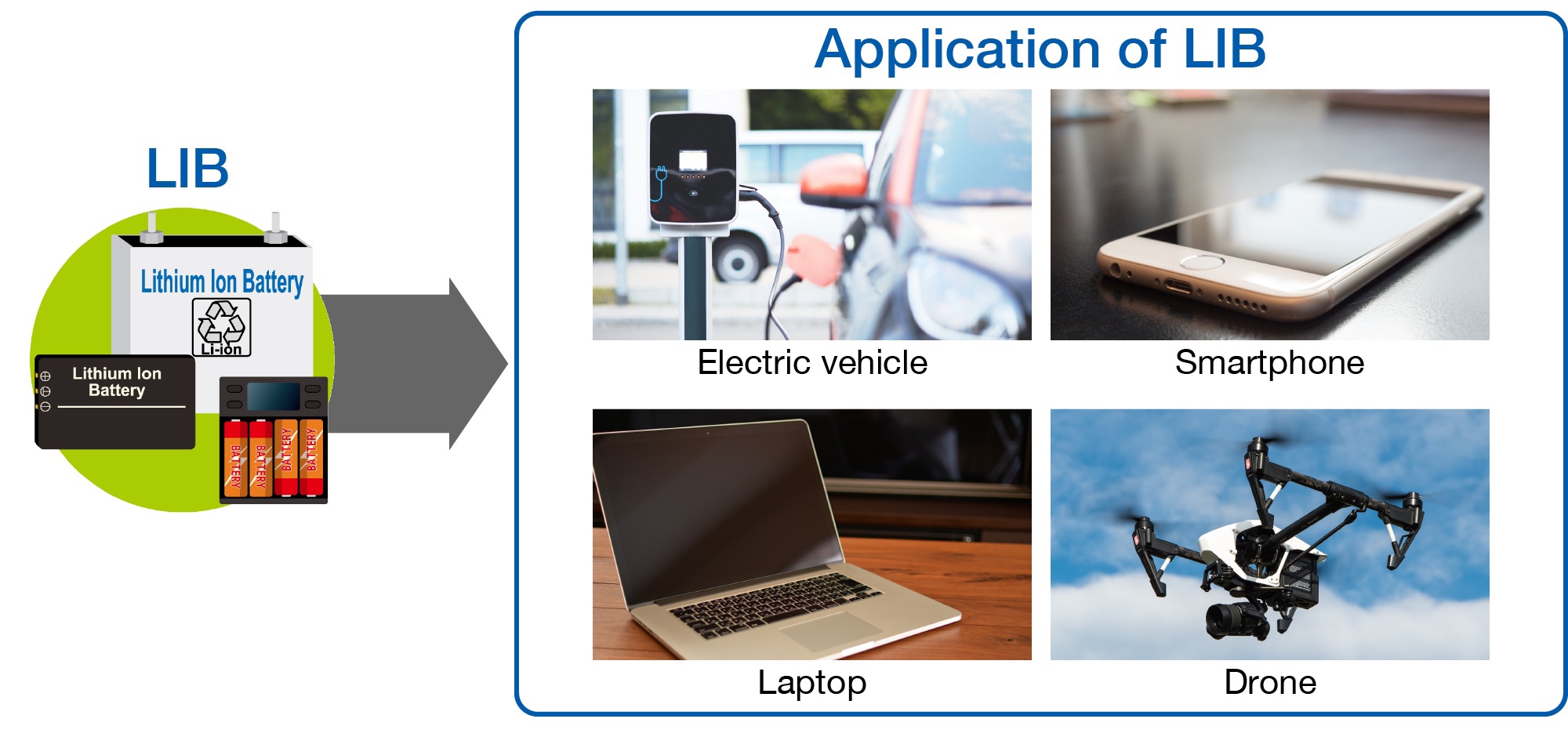

~electrolyte component for lithium-ion battery

Lithium-ion batteries are storage batteries installed in electric vehicles(EVs).

Major application of highly purified carbonate solvent- electrolyte component for lithium-ion battery

The electrolyte used in lithium-ion battery generally consists of a mixed solvent of the following five types of organic solvents, lithium salts and additives.

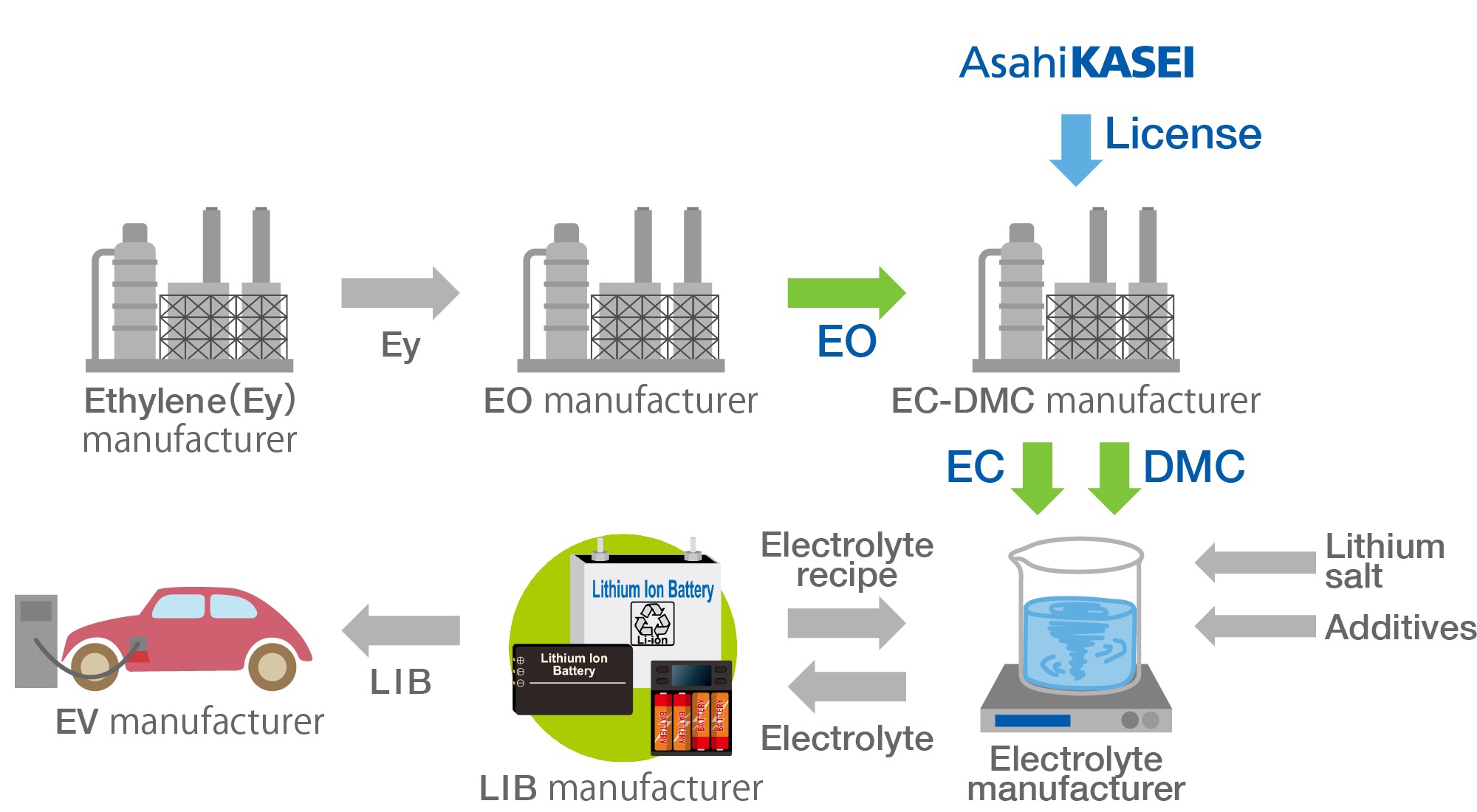

Highly purified EC and highly purified DMC produced by our technology

have realized extreme high purity and can be applied for electrolyte component.

Highly purified EC and highly purified DMC produced by our technology

are prepared into electrolyte by an electrolyte manufacturer, transported to a LIB manufacturer, and used as a LIB material.

We believe

it also necessary to make components of LIB electrolyte used for EVs that don’t emit CO₂ and are environmentally friendly, using environmentally friendly technology.

In fact,

we have received many inquiries to our highly purified carbonate production process technology from many manufacturers in Europe and other countries with high environmental awareness, and are proceeding with licensing activities around the world.