豐田:開設純電動車全固態電池工廠

-帝邦工廠的全固態電池生產線-

– 明智工廠 BEV 的 Gigacast –

我們將提供 Car Watch 上發表的文章摘要。

This time we will be revealing 3 factories:

Toyota will release a battery EV in 2026.

Startup studio “Teiho Factory”

Akechi Factory, which produces engines etc.

“Motomachi Factory” produces BEV, FCEV, PHEV, and HEV

Toyota will organically link its three plants.

![全固体電池、ギガキャスト、匠の技……革新技術とデジタルを融合 トヨタがものづくりの現場を公開した理由【トヨタモノづくりワークショップ2023_1】 | Motor-Fan[モーターファン]](https://motor-fan.jp/mf/wp-content/uploads/sites/4/2023/09/teiho-1024x580.jpeg)

Teiho Factory Startup Studio:

Teiho Factory is a workshop that creates something from nothing.

Consider “How can we make it more efficiently?”

Improving stator magnetic flux density:

I would like to use square wire to increase the magnetic flux density of the stator. Until now, they were made by winding round wire.

The 4th generation Prius was the first to use a flat wire stator.

/cloudfront-ap-northeast-1.images.arcpublishing.com/sankei/J4CZEDGOHBLQTKC6LGUQPAUE2M.jpg)

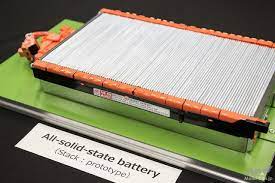

Teiho factory’s all-solid-state battery production line:

The Teiho factory has an all-solid-state battery production line, with the aim of putting it into practical use between 2027 and 2028.

All-solid-state lithium-ion battery cell:

This is different from the “conventional production process that opens the curtain on liquid-infiltrated LIB.”

Batteries are made using a process in which the electrodes are stacked in close contact without damaging them.

Adopts “Karakuri” mechanism:

What was released to the press was the “karakuri” mechanism for making battery cells.

A synchronous control “karakuri” mechanism was adopted.

The “Karakuri” mechanism actually shows how it is accumulating.

This is where Toyota’s accumulated production technology is put to use.

Akechi Factory Gigacast:

Utilizing casting technology for motorsport engines for gigacast production.

Akechi Plant introduced “Toyota’s advanced casting technology and Gigacast production.”

Toyota’s advanced casting technology:

In casting, when creating a complex shape, ”sand is used to create something called a core.”

Motorsport engine core:

Complex cooling water channels must be made thin.

The manufacturing and combination of cores is extremely important.

Integrated molding with Gigacast:

With this advanced casting technology as a background, we will prototype Gigacast.

The rear of the car will be integrally molded using a 4,000-ton casting facility.

Gigacast for BEV:

The company has released “Technology and manufacturing equipment for BEV to be released in 2026.”

Prototype and manufacturing development is currently underway.

We are currently checking the product shape and flow of molten aluminum.

Next-generation BEV productivity:

Toyota will release the next generation battery EV in 2026.

Achieve 1/2 process, 1/2 factory investment, and 1/2 production lead time.

It uses a “3-division module structure, self-propelled production, and digital twin” (front, middle, and rear).

Self-driving BEV production:

I actually saw a bz4X test vehicle running on the line.

The line on which this battery EV runs on its own is also amazing.

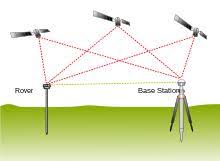

BEV VLR automated transport:

Toyota is working on automating outdoor work using VLR (Vehicle Logistics Robot).

Significantly reduces the amount of work required to wait in line. RTK-GNSS allows positioning at the cm level.