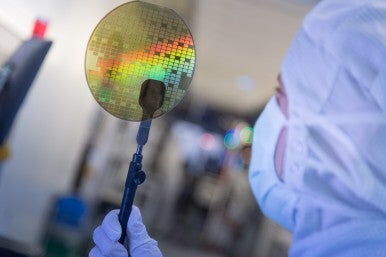

德国博世:300毫米晶圆厂,10亿欧元投资:SiC器件生产

德国博世:

我们生产现有的工厂数据和SiC器件。

通过使用SiC功率半导体,预计EV里程将比以前的车型增加6%。

日产:“叶子”的例子

在WLTC模式下,电池容量为62kWh的模型的里程为458km。

计算使用SiC功率半导体将行进距离增加到485km。

SiC功率半导体:

通过抑制热量损失和提高可操作温度来降低冷却机构的成本。

也有可能减少电池容量。

可以减少占电动汽车成本大部分的电池成本,从而降低汽车价格。

MONOist

https://monoist.atmarkit.co.jp/mn/spv/1910/09/news051.html

Bosch Claims Better Chips Can Increase EV Range

Now Bosch

has announced it is building a factory in Dresden, where it will use 300 millimeter silicon carbide disks to make a new kind of semiconductor.

What’s the big deal?

Using larger discs

drives down the cost of manufacture and the new chips transmit electricity about 6% more efficiently than conventional chips.

Greater efficiency

has several benefits for electric cars. It means a car can travel about 6% further on a single charge.

That can make consumers happy — 6% more range means 265 miles for a car currently rated at 250 miles —

or it can allow companies to decrease the size of the batteries they need to get the range their cars need to be competitive.

Smaller batteries also cost less, which means companies can lower the selling price of their electric cars to boost sales.

Greater efficiency means less electricity is lost to heat during charging and driving.

Less heat means smaller cooling systems, which can also save manufacturers money.

According to SlashGear, the new silicon carbide semiconductor design

has better electrical conductivity than existing chips, thanks to more carbon atoms being packed in during the manufacturing process.

That means

the electronics can achieve higher switching frequencies while also losing less power in the form of heat.

CleanTechnica

https://cleantechnica.com/2019/10/09/bosch-claims-better-chips-can-increase-ev-range/