東麗的電極材料:實現無稀土LIB!

– 高耐久性氧化鋯球的量產技術 –

東麗:

用於鋰離子電池等

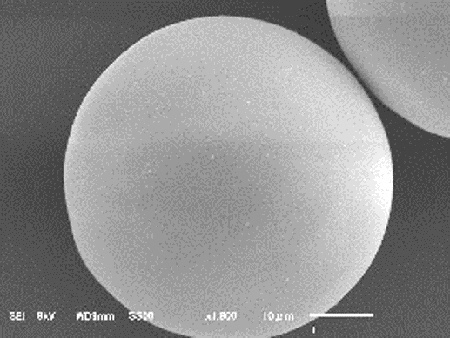

我們開發了一種量產技術,用於生產高耐用性的氧化鋯球,這是一種不含稀土的電極材料。

氧化鋯球是:

氧化鋯球主要用於“粉化物料的分散、粉碎、表面拋光等”。

高性能陶瓷

“特雷瑟姆”

ー東麗的高性能陶瓷“TORAYCERAM”ー

“Torayceram”將用於“鋰離子電池等的電極材料”。

ーEV用鋰離子電池和電極材料ー

需要“大量生產耐劣化和磨損的氧化鋯球”。

降低成本的需求非常嚴峻,挑戰在於延長氧化鋯球的使用壽命。

回复

https://response.jp/article/2023/04/13/369863.html

Matériaux d’électrodes de Toray : réaliser LIB/Rare Earth Free !

– Technologie de production de masse pour des boules de zircone très durables –

Toray :

Pour les batteries lithium-ion, etc.

Nous avons développé une technologie de production de masse pour des boules de zircone très durables, qui est un matériau d’électrode sans terre rare.

Les billes de zircone sont :

Les billes de zircone sont principalement utilisées pour “la dispersion, le broyage, le polissage de surface, etc. pour le poudrage des matériaux”.

céramique haute performance

“Trécerum”

ーLa céramique haute performance de Toray “TORAYCERAM”ー

“Torayceram” sera utilisé pour les “matériaux d’électrodes pour batteries lithium-ion, etc.”

ーBatteries LIB et matériaux d’électrodes pour véhicules électriquesー

Il y avait une demande pour “la production en série de billes de zircone résistantes à la détérioration et à l’usure”.

La demande de réduction des coûts était forte et le défi consistait à prolonger la durée de vie de la bille en zircone.

réponse

Elektrodenmaterialien von Toray: Realisierung von LIB-frei von seltenen Erden!

– Massenproduktionstechnologie für hochbeständige Zirkonia-Kugeln –

Toray:

Für Lithium-Ionen-Akkus etc.

Wir haben eine Massenproduktionstechnologie für hochbeständige Zirkonia-Kugeln entwickelt, die ein seltenerdfreies Elektrodenmaterial ist.

Zirkonkugeln sind:

Zirkonoxidkugeln werden hauptsächlich zum “Dispergieren, Zerkleinern, Oberflächenpolieren usw. zum Pulverisieren von Materialien” verwendet.

Hochleistungskeramik

“Trecerum”

ーTorays Hochleistungskeramik „TORAYCERAM“ー

„Torayceram“ wird für „Elektrodenmaterialien für Lithium-Ionen-Batterien etc.“ verwendet.

ーLIB-Batterien und Elektrodenmaterialien für Elektrofahrzeugeー

Es bestand eine Nachfrage nach einer „Massenproduktion von Zirkonoxidkugeln, die gegen Verschleiß und Abnutzung beständig sind“.

Die Forderung nach Kostenreduzierung war groß, und die Herausforderung bestand darin, die Lebensdauer der Zirkonia-Kugel zu verlängern.

Antwort

Toray Innovates Rare Earth-Free Zirconia Ball Mass-Production Technology to Revolutionize Electronic Component, Electric Car, and Battery Performances

Latest News | Toray Industries, Inc. | TORAY

Apr. 12, 2023 Toray Industries, Inc. Tokyo, Japan, April 12, 2023

– Toray Industries, Inc.,

announced today that it has developed the world’s first mass production technology for rare-earth-free zirconia balls.

The highly durable balls

could grind and mill ceramic materials for multilayer ceramic capacitors (MLCCs) and electrode materials for lithium-ion batteries.

This advance could enhance the reliability diverse products and stabilize their supplies.

It could help customers cut manufacturing costs by replacing balls less frequently.

Toray will initiate sample work early in the fiscal year ending March 2024.

It aims to begin mass production by the close of the term.

The prime application of zirconia balls

is to disperse and powderize materials and polish surfaces.

The company developed Torayceram™ high-performance ceramics, used in ceramic materials for MLCCs and electrode materials for lithium-ion batteries.

The growing sophistication of smartphones in recent years

has increased demand to improve the reliability and supply stability of raw materials for products.

The use of zirconia balls as electrode materials for lithium-ion batteries in electric vehicles and other applications should grow.

This has intensified pressures to cut costs and develop more durable zirconia balls.

Toray thus developed a mass production technology that minimizes the degradation of crystal structures on zirconia ball surfaces.

It redesigned part of the structure of these balls, making them much more durable that conventional counterparts.

This minimizes contamination from zirconia balls

in grinding and milling ceramic materials for MLCCs and electrode materials for lithium-ion batteries, improving and stabilizing the quality of target substances.

The redesigned structure enables sintering at 1,300°C or less, compared with 1,500°C for regular processes, for lower carbon dioxide emissions.

Another key benefit of Toray’s technology is that it is free of yttria, a rare earth metal oxide that is a common stabilizer in zirconia balls.

This eliminates country of origin tracing concerns.

The company will take advantage of the high durability of its technology by exploring ways to regrind the surfaces of zirconia balls and recycle them.

It will accordingly collaborate with customers in evaluating a recycling system to help reach Sustainable Development Goals.

https://www.toray.com/global/news/details/20230411173955.html

Zirconia ball, Top Quality Grinding media and milling media Inovatec

https://www.shinysmooth.com/zirconia-ball

Grinding Media – Union Process