NTT 和三菱重工:成功實現雷射供電

1. 透過光學無線技術為無人機和高空高壓電源 (HAPS) 供電

2. 太空衛星通訊供電也指日可待

以下是《鑽石週刊》一篇文章的摘要。

NTT and Mitsubishi Heavy Industries:

On September 17, 2025, NTT and Mitsubishi Heavy Industries successfully demonstrated “laser wireless power transmission.”

Using laser light, power was supplied to a location 1 km away via “laser wireless power transmission.”

1. Aiming to provide power to disaster-stricken areas, remote islands, drones, and HAPS.

2. The plan is to “power space data centers and lunar rovers” using solar power generated in space.

NTT and Mitsubishi Heavy Industries: Uses 1kW output laser beam

1. A “demonstration experiment of transmission to equipment 1 km away” was conducted at Nanki-Shirahama Airport in Wakayama.

2. The two parties projected a 1kW laser beam from January to February of this year.

Natsuha Ochiai, NTT Space Environment and Energy Laboratories

There have been very few successful examples of wireless power transmission over distances of several kilometers in environments with strong atmospheric turbulence.

Demonstration Experiment of Transmission to a Device 1km Away: World’s Highest Transmission Efficiency

1. The wireless power transmission device was confirmed to be able to obtain 152W of power.

2. The experiment was conducted in a terrestrial environment with strong atmospheric turbulence, and used standard silicon solar cells.

This represents the world’s highest efficiency demonstration of optical wireless power transmission.

Laser Light Wireless Power Transmission: Features and Challenges

1. Laser light is transmitted into space and irradiated onto a photovoltaic conversion panel.

2. This technology allows remote devices or centers to supply power.

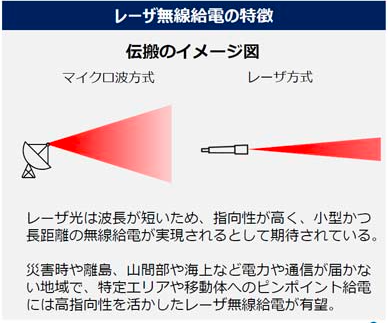

3. With microwave power transmission, the microwave beam width is wide, resulting in larger equipment.

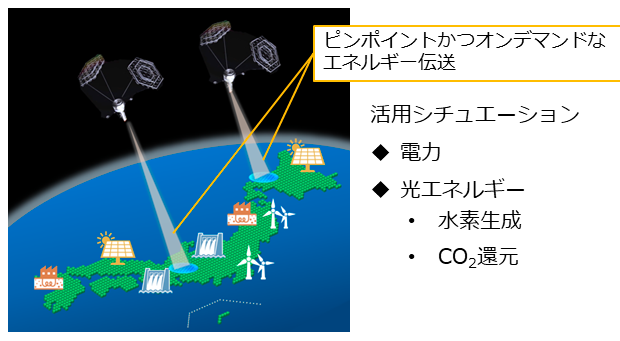

Laser wireless power transfer is far more advantageous for “pinpoint power transfer to specific areas or moving objects.”

Background to the need for laser wireless power transfer:

However, laser wireless power transfer methods also have challenges.

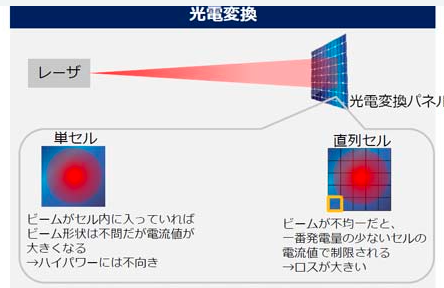

1. Photovoltaic conversion panels are collections of elements that convert light into electricity, and uniform beam irradiation to each element is required.

2. If the beam does not hit a specific cell, the power output will be limited because the elements are connected in series.

In addition, atmospheric turbulence can cause the beam position to shift, causing unevenness in the beam intensity distribution and reducing photovoltaic conversion efficiency.

Challenges with laser wireless power transfer:

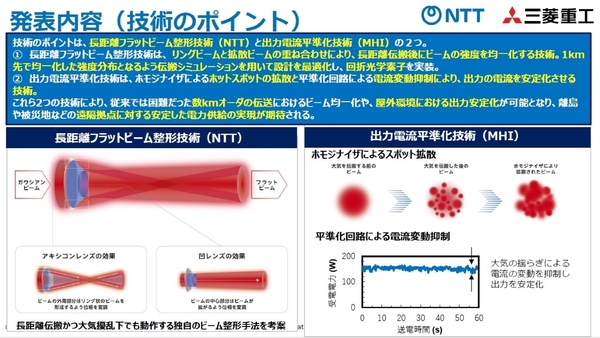

NTT’s “long-distance flat beam shaping technology” and Mitsubishi Heavy Industries’ “output current leveling technology” solve these challenges.

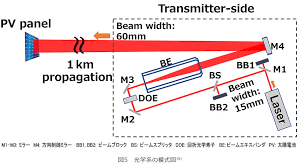

NTT: “Long-distance flat beam shaping technology”:

NTT’s “long-distance flat beam shaping technology” homogenizes the beam intensity distribution at the laser light source.

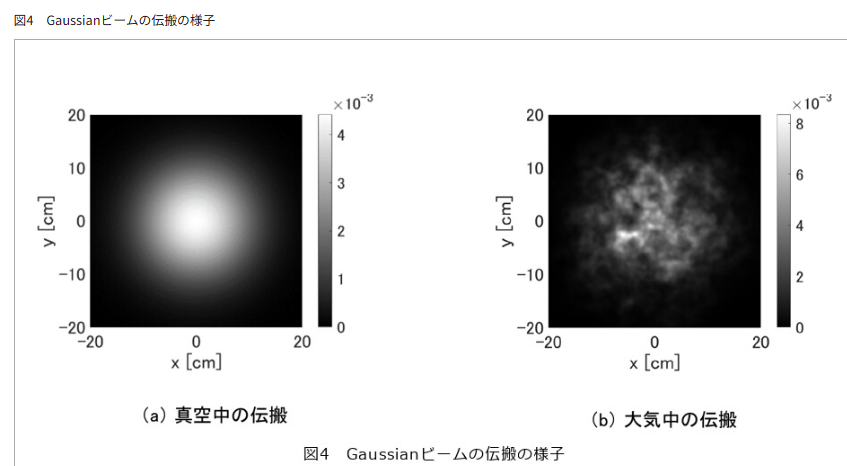

Typically, laser beams (Gaussian beams) have a Gaussian (normal) intensity distribution.

If propagated as is, the beam would not be uniformly directed at the light-receiving panel.

1. Therefore, different phases are given to the outer and central portions of the beam.

2. The beam is shaped so that the intensity distribution is flat at a distance of 1 km.

Ring beam and diverging beam: Superposition:

1. A conical lens called an axicon lens is used on the outer portion of the beam.

2. The phase is modulated to form a ring-shaped beam (ring beam).

A concave lens is used in the central portion:

3. On the other hand, a concave lens is used in the central portion to modulate the phase so that the beam spreads (diverging beam).

4. By superimposing this ring beam and diverging beam, the intensity is flattened after propagation.

“By optimizing for distance, distances of over 1 km can be achieved.”

Mitsubishi Heavy Industries: “Output Current Leveling Technology”:

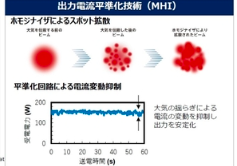

MHI’s “output current leveling technology” equalizes the intensity distribution of a laser beam at the receiving end.

1. When a Gaussian beam propagates through atmospheric turbulence, the intensity distribution is disrupted, creating intense spots.

2. By diffusing these spots using a device called a homogenizer, the beam is uniformly directed at the receiving panel.

3. Furthermore, by connecting a capacitor to the photoelectric conversion element cell, current fluctuations caused by atmospheric turbulence are suppressed.

These two technologies:

achieve beam uniformity over transmissions of several kilometers and output stabilization in outdoor environments, which are difficult to achieve with conventional beam shaping technology.