三菱重工車載加氫站:配備超高壓液氫和增壓泵

-新開發超高壓液氫增壓幫浦-

-排氣壓力90兆帕的氫氣填充能力-

我們將提供在 News Switch 上發表的文章摘要。

Mitsubishi Heavy Industries and Iwatani:

An ultra-high pressure liquid hydrogen booster pump will be installed on the truck.

The ultra-high pressure liquid hydrogen and booster pump will be loaded onto the bed of a truck and transported.

Mobile pump type on-vehicle hydrogen station:

The hydrogen filling capacity has been significantly improved compared to existing in-vehicle models.

It will be used in “places where it is difficult to install a stationary hydrogen station,” such as ports and construction sites.

Hydrogen will be filled into “FC-equipped next-generation port cranes and hydraulic excavators.”

Major manufacturers in the world:

We are proceeding with the development of FC-equipped port cranes.

In the future, the hydrogen filling environment will become an important issue for widespread use.

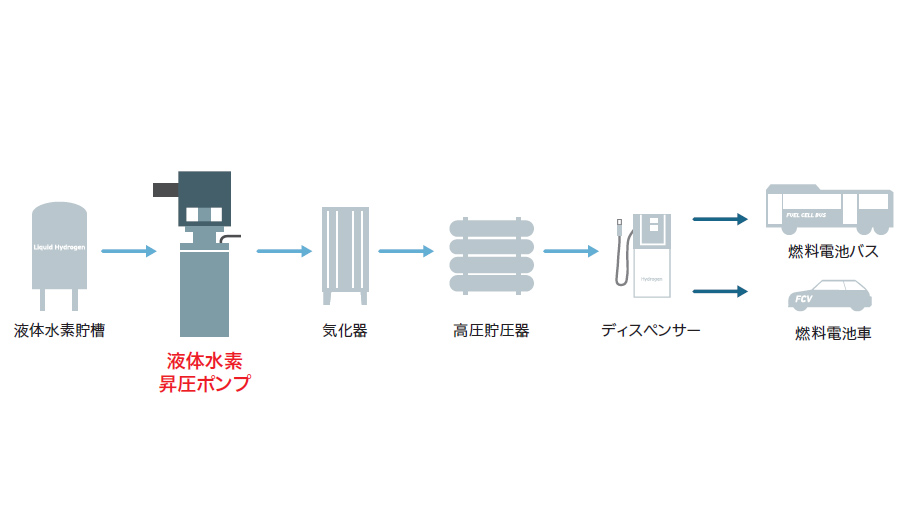

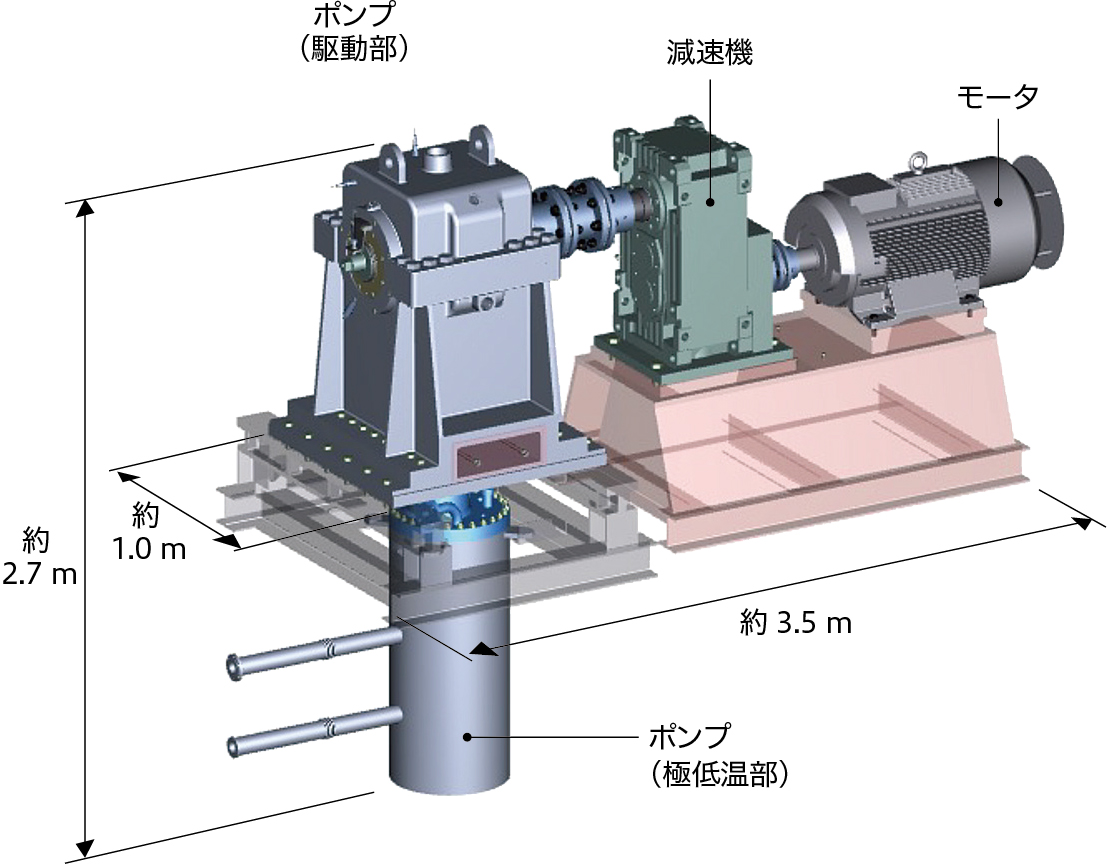

MHI’s ultra-high pressure liquid hydrogen boost pump

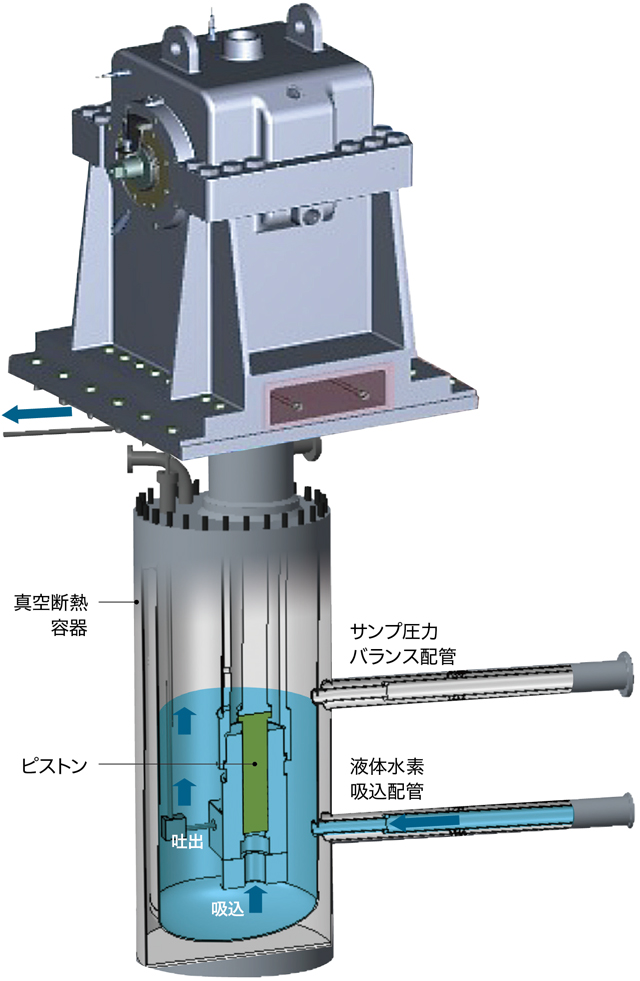

An ultra-high pressure liquid hydrogen booster pump with a discharge pressure of 90 megapascals developed by Mitsubishi Heavy Industries for hydrogen stations.

Power consumption is 1/4th:

Power consumption is 1/4th that of the “compressor method that boosts pressure at hydrogen stations.”

Compared to the compressor method, the number of component pressure accumulators can be significantly reduced.

Hydrogen station construction and operation:

Utilizing Iwatani Sangyo’s knowledge of hydrogen station construction and operation.

Iwatani Sangyo has also successfully completed a 1,000-hour long-term durability test on a stationary hydrogen station.

The aim is to deliver the product to customers in 2024.

Mitsubishi Heavy Industries’ new hydrogen pump: Succeeded in continuous operation for 250 hours

We will deliver a summary of articles published in News Switch.

MHI and First Element Fuel (FEF)

90 megapascal class ultra-high pressure liquid hydrogen boost pump for hydrogen stations.

Successful long-term durability test with a total of 250 hours of operation.

Long-term durability test:

MHI jointly conducted the project with FEF in California, USA.

Confirmed that FCV can be stably filled with fuel hydrogen.

It will be tested in the United States until 2024 and sold to liquid hydrogen stations around the world.

Start/stop operation 300 times:

30 tons of liquid hydrogen was pressurized for 1,100 FC buses.

The soundness and durability of various parts, including consumables, were confirmed.

Check the durability of parts:

With a discharge pressure of 90 megapascals,

Approximately 160 kg per hour,

High flow rate operation was carried out continuously and stably.